TECHNICAL SPECIFICATIONS

Sodium Silicate Powder With Brand Name

Note :

If Sodium silicate liquid is desired mix the powder in water ( not exceeding 38% ) by weight of water and immediately stir vigoursly for at least 10 mins, failure to stir initially can lead to formation of lumps which will be slow in dissolving.

CHARACTERISTICS

The various powdered sodium silicate are distinguished by one or more of the following characteristics ,

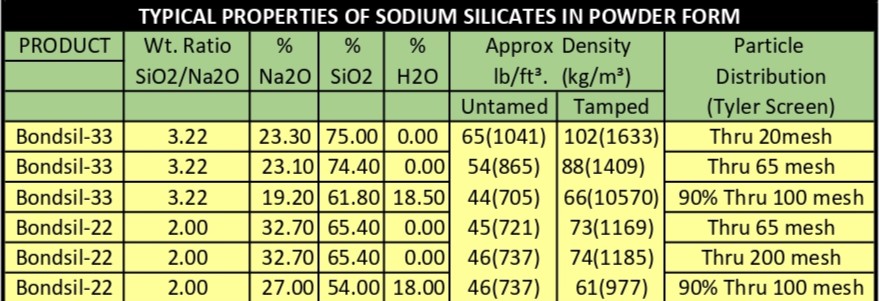

Anhydrous (Water - Free) Sodium silicate glass is available as powders of various particle size at the same SiO2/Na2O ratios as the two more popular commercial liquid silicates. Hydrates products at the same ratio are offered for their more rapid rate of solution. The various powdered silicates and their composition is listed in Table - 2

TECHNICAL ADVICE

Table 2 lists some common uses for sodium silicate powders, the properties discussed in this bulletin may suggest new uses, Technical Representation will be happy to discuss individual requirements , submit samples, and provide application assistance For More Information Contact Us :

ADVANTAGES :

Quantum Of Use:

It will be difficult to recommend exact percentage of Bondsil as the quantity depends your brand positioning and targetted market segment, however a use of 5% to 12 % Bondsil can be suggested.

Effects Of Silicate (Bondsil) Composition:

The more alkaline silicate import creator plasticity to cement structures and result in higher green strength, concentrated wet mixes may some what sticky. The tendency of low ratio silicate to fuse at high temperatures may be offset in practice by the fact that less of it is needed to obtain good strength at a given consistency, a refractory cement made from a more highly alkaline silicate will contain less water making for denser structure with less shrinkage.